At Advanced Gauging Technologies (A.G.T.), we’ve spent decades building something pretty special — a cutting-edge company with deep roots, strong values, and a tight-knit team that’s passionate about what we do.

Now, we’re growing — and we need smart, ambitious, people-oriented individuals to help us do it.

That’s where you come in.

👀 Who We’re Looking For:

We’re hiring internal sales professionals to join our crew in the Dublin, Ohio area. You don’t need 10 years of experience. What you do need is drive, confidence, and a genuine interest in helping people solve problems.

If you’re someone who:

-

Loves building relationships and isn’t afraid to pick up the phone

-

Is curious about high-tech equipment (ours is used in everything from steel mills to high-end manufacturing)

-

Gets excited by the idea of turning conversations into connections — and connections into deals

-

Wants to be part of a fast-growing company where your voice actually matters

…then you might be exactly who we’re looking for.

📦 What You’ll Be Selling:

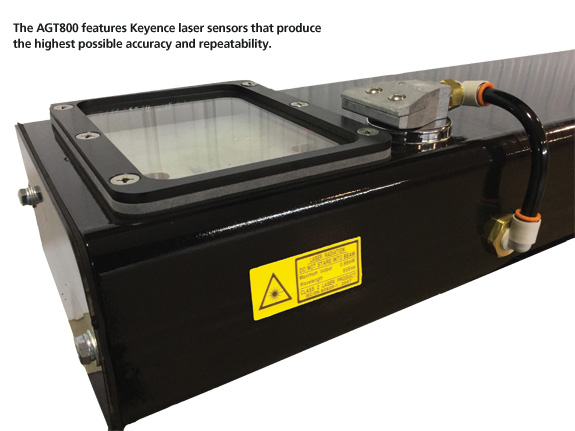

A.G.T. specializes in non-contact thickness gauging systems — sleek, high-tech tools that help manufacturers ensure their products are up to spec, every time. We’re not selling “just another product” — we’re selling reliability, accuracy, and peace of mind to industries that need it.

And with clients across the U.S., Canada, and Mexico, there’s no shortage of people to talk to.

💥 Why This Is a Big Deal:

This is a chance to get in early and grow with us. You’ll work directly with leadership, help shape our sales strategy, and develop your skills in an environment where ideas are encouraged, effort is rewarded, and career growth is real.

🎯 Perks + Benefits:

-

Competitive salary + bonus potential

-

Health, dental, vision & life insurance

-

SIMPLE IRA with company match

-

Paid time off

-

Casual dress code, flexible mindset

-

In-house fitness program (yeah, we believe in work-life balance)

-

A culture that actually values you

📍Location:

On-site in Dublin, OH — right near Columbus, in a cool office with a great team and a lot of potential.

✨ Sound Like You?

Whether you’re fresh out of school or just ready for a fresh start, this is your shot to do meaningful work in a place that’s going places. We’re not looking for cookie-cutter candidates — we’re looking for people with heart, hustle, and a hunger to grow.

Ready to make your mark?

Shoot your resume and a quick intro to 📧 Jobs@AdvGauging.com.

We can’t wait to meet the next big part of our team — maybe it’s you.